The production process

Our key concerns during the production process are hygiene, quality and sustainable energy use. The Pur Natur production plant is IFS certified (high level) and our laboratory sets stringent quality standards against which all raw materials and end-products are carefully tested.

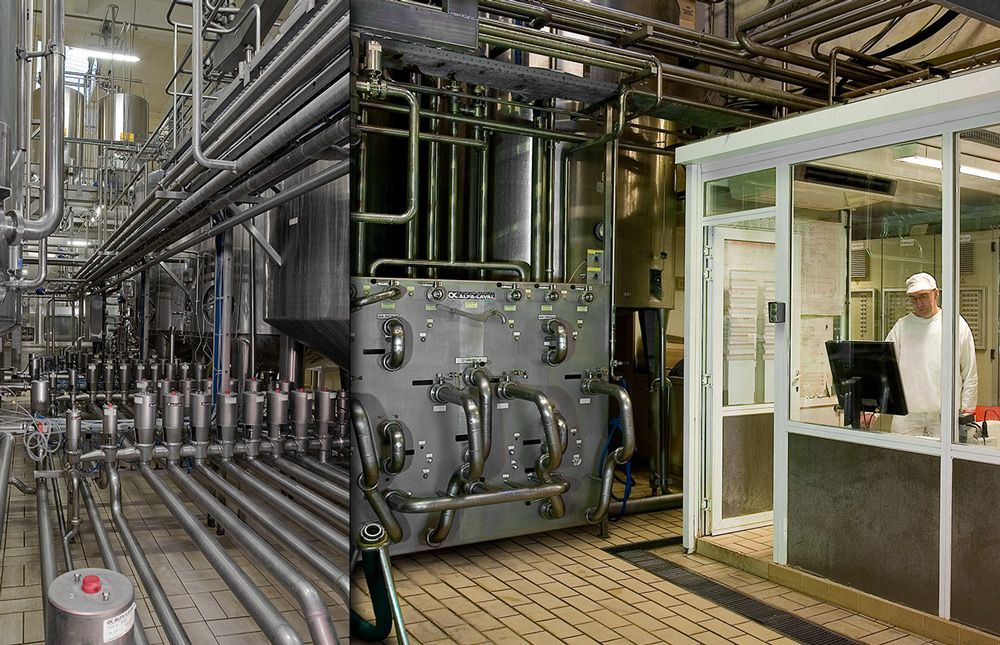

From there the milk is automatically prepared for the production of quark and yoghurt and subsequent insertion into packaging containers. These quarks and yoghurts are transported to the filling area by means of an ingenious system of pipes and tanks. All our filling machines use laminar flow (overpressure), which ensures that stringent standards of hygiene are maintained at all times. Fruit and yoghurt are injected into sterile pots.

Our unique set yoghurt is fermented in the pot while housed inside the incubator unit.

All products are assigned a batch number and an expiry date. They are then ready to be put on pallets. Finally, the freshly-made products are prepared for dispatch and stored in refrigerated warehouses.